Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

- Type:

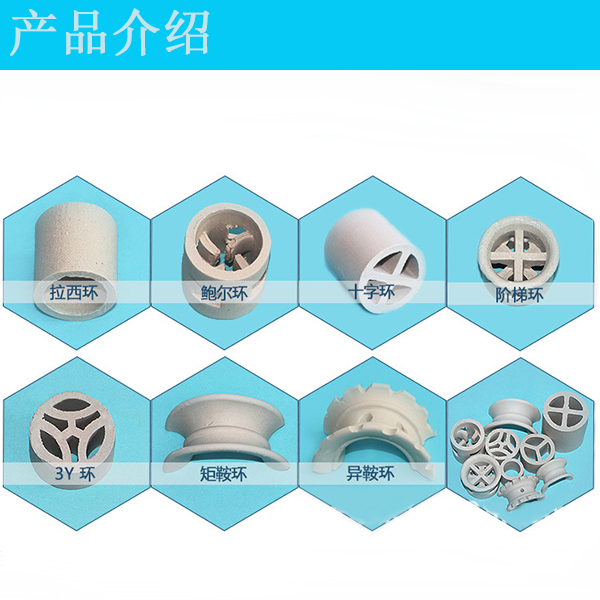

Ceramic Rings, Ceramic random packing Tower packing

- Application:

Industrial Ceramic, Adsorption, Scrubbing, Stripping, All kinds of Separation

- Material:

Alumina Ceramic, Alumina Ceramic

- Model Number:

Ceramic Tri-Y rings

- Brand Name:

HE ZHONG

- Product Name:

Ceramic Tri-Y rings

- Alumina Content:

17-23%

- Size:

16mm,25mm,30mm,38mm,50mm,or customized

- Certificate:

ISO9001:2015

- Free Sample:

Yes

- Package:

Jumbo bag, carton box, wooden case, or customized

Supply Ability

- Supply Ability:

- 10000 Cubic Meter/Cubic Meters per Month

Packaging & Delivery

- Packaging Details

- 1 m3/Jumbo bag,

bulk in Normal PP Woven bag/wooden case/carton box

- Port

- Shenzhen/Shanghai

- Lead Time :

- Shipped in 5-15 days after payment

Wholesale Alumina Ceramic Tri-Y packing Rings with high quality 批发高品质氧化铝陶瓷三Y包装环

Product Description

Ceramic three-y ring packing is a new type of high-efficiency bulk packing with unique appearance design and processing. The product's high-diameter ratio is about 2:1, and there is one or three "Y" type baffles inside, so as to increase the specific surface area, improve the vapor liquid dispersion performance, and make the vapor liquid contact more fully.

The three-y ring filler is improved from the step ring, conjugate ring, flat ring and moment saddle ring on the basis of the shape, appearance and structure of comprehensive consideration.Its main characteristics are unique and superior structure, large ventilation capacity, large specific surface, uniform gas-liquid distribution, pressure reduction, high strength, gas-liquid mass transfer performance than the general filler.

Ceramic three-y ring packing is suitable for: chemical industry, petroleum, chemical fertilizer, sulfuric acid, fine chemical industry, pharmaceutical, environmental protection and other industries.

Ceramic mainly on three Y pingxiang local high-quality kaolin, quartz and feldspar as a raw material, ingredient, ball mill, vacuum pug, die design, extrusion molding, drying, sintering and other processing of a new type of high quality SanDui ceramic packing. Because of the excellent craft processing conditions, such as raw materials selection, vacuum extrusion molding, strictly control the flame atmosphere in sintering process, product has ceramic density, colour and lustre is uniform, high mechanical strength, resistance to pressure, good thermal shock resistance, resistance to handling is not damaged.At the same time, the product structure space performance is good, in the filler bed use ventilation volume is large, larger than the surface, gas-liquid distribution uniformity, small resistance, pressure reduction, high strength, gas-liquid mass transfer performance is better than the general filler.

| Product Name | Item | Size D*H*T(mm) | Number per m3 | Surface Area m2/m3 | Free Volume

% | F factor

m-1 |

| Tri-Y Ring | Φ16 | 16x10x1.5 | 300500 | 368 | 72 | 406 |

| Φ25 | 25x13x2 | 87040 | 240 | 74 | 390 |

| Φ30 | 30x16x2.5 | 55000 | 190 | 74 | 310 |

| Φ38 | 38x20x3.5 | 27600 | 160 | 75 | 260 |

| Φ50 | 50x30x4.5 | 10100 | 138 | 75 | 233 |

陶瓷三Y环

一、产品简介

陶瓷三Y环填料是一种经外观独特设计加工成的一种新型高效散堆填料,产品高径比约为2:1,内部设有一个或三个“Y”型隔板,这样增大比表面积,提高了汽液分散性能,使汽液接触更充分。

三Y环填料是从阶梯环、共轭环、扁环、矩鞍环的基础上以及在形状、外观和结构综合考虑,进行取长补短而改进的。其主要特点是结构独特优越、通气量大、比表面大、气液分布均匀、压降低、强度高、气液传质性能比一般填料好。

陶瓷三Y环填料适用于:化工、石油、化肥、硫酸、精细化工、制药、环保等行业,先后在广东新华粤石化股份有限公司、中石化南化集团设计院、北京迪威尔石油天然气开发股份有限公司等厂家得到应用,效果相当良好。

陶瓷三Y环主要以萍乡本地产优质高岭土与石英、长石等为原料,经配料、球磨、真空练泥、模具设计、挤压成型、干燥、烧结等加工而成的一种新型优质散堆陶瓷填料.因优异的工艺加工条件,如原料优选,真空挤压成型,严格控制烧结工艺中的火焰气氛,产品具有瓷质致密,色泽均匀,机械强度高,耐压力冲击,抗热震性能好,耐搬运不破损。同时产品结构空间性能好,在填料床层使用通气量大、比表面大、气液分布均匀、阻力小、压降低、强度高、气液传质性能比一般填料好。

二、技术参数

陶瓷三Y环填料特性参数

规格

D×H×S(mm) | 比表面积m2/m3 | 空隙率

% | 堆积个数

n/m3 | 堆积重度

kg/m3 |

Φ16×10×1.5 | 250 | 87 | 300500 | 1150 |

Φ25×16×2.0 | 180 | 85 | 87040 | 800 |

Φ30×18×2.5 | 170 | 85 | 55000 | 850 |

Φ38×23×3.5 | 140 | 85 | 27600 | 905 |

Φ50×30×4.5 | 110 | 84 | 10100 | 880 |