Professional supply grade 75 content of high aluminum ball enamel, ceramic fireproof ball 专业供应优级75含量中高铝球 搪瓷、陶瓷专用 耐火球

Inert Ceramic Balls are available in different diameter from 2mm to 75mm per customer request. The Ceramic balls’ alumina content could also be 17%, 19%, 25%, 50%, 65%, 70%,95%,99%. Alumina Ceramic Balls have stable chemical features and a low rate of water absorption, Inert Alumina balls can resist high temperatures and high pressure. Inert Alumina ceramic balls can also resist the corrosion of acid, alkali and some other organic solvents, Inert Alumina ceramic balls are able to stand the thermal shock (quick change of temperature) during the manufacturing process. The main role of these Inert Alumina ceramic balls is to increase the distribution spots of gas or liquid, and to support and protect the activating catalyst of low strength in the reactors and column/tower.

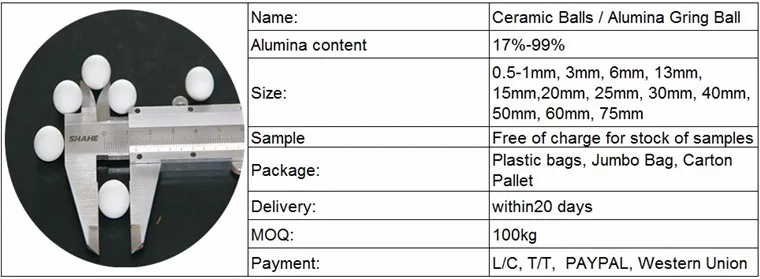

Specification

A host-crystal | feldspathic | feldspar mullite nature | mullite nature | mullite corundum nature | corundum nature |

Al203 content(%) | 20-30 | 30-45 | 45-70 | 70-90 | ≥99 |

Water absorption(%) | ≤5 | ≤5 | ≤5 | ≤5 | ≤1.5 |

the acid resistance(%) | ≥98 | ≥98 | ≥98 | ≥98 | ≥98 |

the fastness to alkali(%) | ≥80 | ≥82 | ≥85 | ≥90 | ≥95 |

Bears the temperature emergency (°C) | ≥1.30 | ≥200 | ≥500 | ≥700 | ≥800 |

the compressive strength KN/grain | Φ3 | ≥0.12 | ≥0.14 | ≥0.15 | ≥0.16 | ≥0.20 |

Φ6 | ≥0.40 | ≥0.42 | ≥0.44 | ≥0.48 | ≥0.50 |

Φ8 | ≥0.48 | ≥0.52 | ≥0.60 | ≥0.62 | ≥0.65 |

Φ10 | ≥0.60 | ≥0.70 | ≥0.80 | ≥0.90 | ≥1.00 |

Φ13 | ≥1.00 | ≥1.10 | ≥1.30 | ≥1.50 | ≥1.80 |

Φ16 | ≥1.50 | ≥1.60 | ≥1.80 | ≥2.30 | ≥2.60 |

Φ20 | ≥1.80 | ≥2.00 | ≥2.30 | ≥2.80 | ≥3.20 |

Φ25 | ≥2.50 | ≥2.80 | ≥3.20 | ≥3.60 | ≥4.00 |

Φ30 | ≥3.00 | ≥3.20 | ≥3.50 | ≥4.00 | ≥4.50 |

Φ38 | ≥4.00 | ≥4.50 | ≥5.00 | ≥5.50 | ≥6.00 |

Φ50 | ≥6.00 | ≥6.50 | ≥7.00 | ≥8.50 | ≥10.00 |

Packing density(kg/m3) | 1300-1400 | 1400-1500 | 1500-1600 | 1600-1800 | 1900-2200 |

High Alumina Ceramic Balls

Al2O3 | SiO2 | Fe2O3 | Na2O | MgO | TiO2 | Proportion (g/cm3) | Porosity rate (%) |

>99% | <0.2% | <0.1% | <0.05% | <0.5% | <0.05% | 3.6-3.8 | <1 |

Application of Alumina Ceramic Balls:

Alumina Ceramic Balls can be used as refractory bed top plugs and supports in order to protect the catalyst bed from thermal impurities so that the catalyst bed is kept intact in spite of wide pressure variation. Inert aluminum Ceramic Ball is widely used in petrochemical industry, chemical industry, fertilizer industry, natural gas industry and environment protection, etc.

Stoneware Catalyst Bed Supports are used routinely in the following specific services: Ammonia plants, Hydrotreaters, Bender treaters, Isomerization units, Chloride absorbers, pretreaters and reactors, Claus units, Molecular sieve units, Diesel hydrotreaters, Naphtha treaters, Fixed bed reformers, Reformer pretreaters, Fluidized pollution control, Hydrocrackers (1st stage), VGO pretreaters, Hydrogen plants.