Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

- Type:

Ceramic Tubes

- Application:

Industrial Ceramic

- Material:

Alumina Ceramic

- Model Number:

HZ-FILTER

- Brand Name:

HE ZHONG

- bulk density:

1.4-1.6g/cm3

- pore size:

10-500um

- max. temperature resistance:

800 C

Supply Ability

- Supply Ability:

- 2000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- wooden carton

- Port

- Qingdao

- Lead Time :

- 20-30days

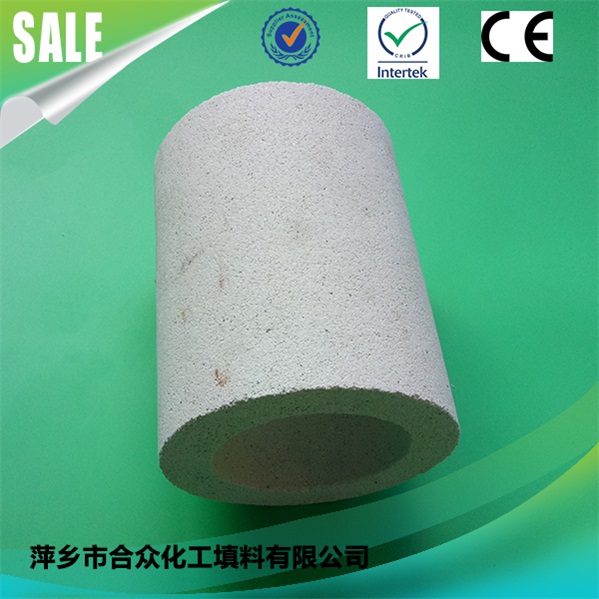

microporous alumina ceramic filter cylinder for ash removal 微孔氧化铝陶瓷除灰过滤筒

1:General Material Description:

This ceramic filter elements are manufactured from high alumina micro porous ceramic material consisting of plenty of well-distributed and arched open holes.

Due to high porosity and the large internal surface,the high alumina porous ceramic offer a high storing capacity for particles and liquids.The labyrinth structure leads to an excellent separation efficiency at a simultaneously very low increase of differential pressure.

The high alumina porous ceramic filter elements are distinguished by the high thermal shock resistance and high bending strength.So that it can be used in depth filtration applications of up to 500oC and easily cleaned and regenerated.

2:Physical Properties:

High Alumina Micro Porous Ceramic Filter Elements

| Unit | |

Bulk Density | g/3cm | 1.4-1.6 |

Pore size | μm | 10-500 |

Porosity | % | 30-50 |

Water Permeability | t/m2h.h | 1.0-2.5 |

Gas Permeability | m3/m2h.h | 1.8-5.0 |

Bending Strength | MPa | 3.5-5.0 |

Compressive Strength | MPa | 12-15 |

Mohs’ hardness | Scal | 6-8 |

Max. Temperature Resistance 1 | oC | 800 |

Thermal Stability | oC | 350 |

3:Chemical Resistance

resistant against most acids, saline solutions and organic solvents, liquid or gas covering the complete acid,neutral and alkali range up to pH 11,exept hydrofluoric acid and fully desalted water.

(Note:As end use conditions can vary,it is the users’ responsibility to verify compatibility with their specific use conditions.)

4:Standard Dimentions:

Type | Item No. | L x W x H (mm) | | Type | Item No. | Do x Di x L (mm) |

Brick | DQHAB-1 | 230×113×65 | | Cylinder | DQHACL-50A | 50×30×500 |

Brick | DQHAB-2 | 230×113×60 | | Cylinder | DQHACL-50B | 50×30×700 |

Brick | DQHAB-3 | 230×113×55 | | Cylinder | DQHACL-80A | 80×50×500 |

Brick | DQHAB-4 | 230×113×50 | | Cylinder | DQHACL-80B | 80×50×700 |

Brick | DQHAB-5 | 230×113×45 | | Cylinder | DQHACL-100 | 100×60×700 |

Brick | DQHAB-6 | 230×113×40 | | Cylinder | DQHACL-120 | 120×80×1000 |

Plate | DQHAP-1 | 230×230×45 | | | | |

Plate | DQHAP-2 | 250×250×55 | | | | |

Plate | DQHAP-3 | 300×300×60 | | | | |

Plate | DQHAP-4 | 330×330×65 | | | | |

Plate | DQHAP-5 | 350×350×60 | | | | |

Plate | DQHAP-6 | 400×400×65 | | | | |

Type | Item No. | Do x Di x L (mm) | Flange(mm) |

Header | Thickness | Width |

Flanged Candle | DQHAFC-50 | 50 x 30 x500 | 66 | 15 | 8 |

Flanged Candle | DQHAFC-75 | 75 x x30 x700 | 88 | 15 | 8 |

Flanged Candle | DQHAFC-100 | 100 x 60 x 700 | 120 | 20 | 10 |

Flanged Candle | DQHAFC-150 | 150 x 100 x 1000 | 180 | 25 | 15 |

Flanged Candle | DQHAFC-200 | 200 x 140 x 1000 | 230 | 30 | 15 |

Flanged Candle | DQHAFC-300 | 300 x 240 x 1000 | 240 | 30 | 15 |

5:Applications:

DQHA ceramic filter elements

DQHA | Applications |

Precoat filter for liquids

| Filtration of beer,water,glucose syrup;beer yeast recovery;

|

Particle filter for gases

| Coarse filter for biogas;

|

Diffuser

| Aeration of potable water(e.g. de-acidification);

|

Fluidization | Hot fluidized bed processes;ash transportation;conveying of red,iron slurry. |

微孔陶瓷过滤管

1、产品概述

微孔陶瓷是由骨料颗粒、分离剂、成孔剂和稀土抗蚀剂四部份组成。经过高温烧结使其外表和内部开成相互连通的桥拱状启齿气孔。当流体从这些气孔中经过时,原水或液体中的悬浮物质、胶体颗粒、大分子有机物被截留在过滤介质表面,流体经过微孔通道产生各种物理效应,达到机械筛滤、净化扩散、流态化等功效。

2、性能特性

微孔陶瓷产品除具有普通陶瓷产品性能外,还具有其共同的特性:

a)除氢氟酸外,对一切腐蚀液均有优秀的耐腐蚀性。

b)耐热性能好,不会产生热变形,在500℃时运用效果不变。

c)耐寒、耐冻性能优秀。

d)微孔散布平均,可按用户请求构成500μm以下各种孔径。

e)由于刚性大,因此在流体压力作用下不惹起外形变化和细孔变形,从而产品应用过程中易于清渣和再生。

f)在液体中无溶出物,因而液体不会遭到二次污染。

3、技术指标

Size/项目 | 指标 | 项目 | 指标 | 项目 | 指标 |

密度(g/cm3) | 1.6-2.0 | 热稳定性(℃) | 350-20 一次不裂 | 透水率(t/m2h) | 10-2.5 |

吸水率(%) | 23.3 | 孔径(um) | 10-500 | 耐碱性(%) | 86 |

耐磨性(%) | 98 | 孔隙率(%) | 30-40 | 透气率(m3/m2h) | 1.8-5.0 |

坑折强度(Mpa) | ≧5.3 | 硬度(莫氏(MOhs’)) | 7 | 抗压强度(Mpa) | 12-16 |

4、主要型号规格 过滤陶瓷砖、板、管的型号规格

型号 | 微孔板 长X宽X高 | 型号 | 微孔砖 长X宽X高 | 型号 | 微孔管 长X宽X高 |

NCB-1 | 250X125X50 | NCZ-1 | 230X113X65 | NG-50 | 60X10X500 |

NCB-2 | 250X250X50 | NCZ-2 | 230X113X60 | NCZ-50 | 60X10X1000 |

NCB-3 | 300X300X60 | NCZ-3 | 230X113X55 | NCZ-80 | 100X20X500 |

NCB-4 | 330X330X60 | NCZ-4 | 230X113X50 | NCZ-80 | 100X20X1000 |

NCB-5 | 500X500X60 | NCZ-5 | 230X113X45 | NCZ-100 | 200X30X500 |

NCB-6 | 700X700X60 | NCZ-6 | 230X113X40 | NCZ-120 | 200X30X1000 |

注:规格尺寸还可依据用户请求作恰当调整。

5、应用范围

微孔陶瓷由于具有耐高温(寒)、耐化学腐蚀、强度高、气孔散布平均,运用寿命长且再生烦琐等优点,在许多行业都能够应用。其应用根本上可分两品种型,一是用于两种物相别离;二是把一种物相分散到另一种物相之中,也就是使两相分离,特别是用于液相过滤、气体过滤、流态化等方面。

在环保范畴内,废水化学混凝后污泥、絮凝体的过滤、脱水;离子交流法、电解法、活性炭吸附法处置废水的预处置;锅炉湿法除尘废水中悬浮物的过滤处置(可完成闭路循环);气浮法与蒸发浓缩的终端处置;含油废水的油水不别离处置;放射性废物燃(焚)烧排气过滤代集放射性物质;放射性废物库或渣滓填埋场做垫层,使之浸透废水经暗沟流入集水池中处置,可避免二次污染;用于烟气过滤,过滤含锌、锡、镍等电镀废水的过滤和电解槽母液的过滤处置,简化了流程,俭省了投资。

在工业范畴内,可用于四环素消费中的晶体过滤;化工双氧水消费中的水质过滤;感光胶片消费中的杂质过滤;立德粉消费中的硫化锌过滤;各种结晶物的过滤等。也可用于自然气过滤;紧缩空气过滤灰尘、水滴、油雾;二氧化碳气体滤除粉尘;过滤各种有机溶剂,脱炭、精制溶液石油开采炼制前除去原油中水份,油水别离等;油田回灌水杂质过滤,过滤蒸气、氯气、氧气、焦炉气、三氧化硫、五氧化二氮、二氧化碳、甲烷、氢气、乙炔、二氧化硫中的尘埃、杂质等;空气、蒸汽消毒过滤等,散气、布气充气,把气体分散到液体中,如有色金属浮选;各种自来水、工业用水、海水淡化、纯水、超纯水制备的过滤处置;各种酒、饮料、葡萄糖的盐水过滤;还可作为催化剂载体等。