Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

- Type:

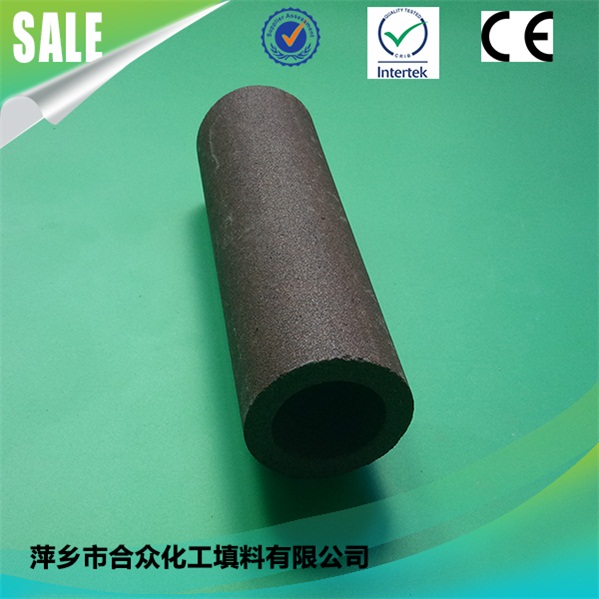

Ceramic Tubes

- Application:

Industrial Ceramic

- Material:

Alumina Ceramic

- Model Number:

Porous Ceramic Filter Pipe

- Brand Name:

HE ZHONG

- ISO 9001:2000:

Certificated

Supply Ability

- Supply Ability:

- 50000000 Piece/Pieces per Year ceramic tube

Packaging & Delivery

- Packaging Details

- 10pcs/carton shock resistance plastic inside for ceramic tube

- Port

- Shanghai port

- Lead Time :

- Within 1 week afer get formal order and payment

There are much size distributing uniformity connecting each other bridge-arch shape open gas pores in the micro-pored ceramic filter medium, when the fluid is passed through the micro-pores, the suspending materials colloid granules big molecule organism are remained on the filter medium surface...

As the fluid is passed through the micro-pored passages, several physical effects happen, this makes mechanism screening refine or diffusion fluidization, etc.

Characteristic:

Enduring corrosion, enduring high temperature, high strength low resistance, no toxicity, easy regeneration and long life.

Purpose:

Abroad utilized for waste effluent treatment is chemical metallurgy power-electricity coal-chemical, nucleus industry etc. Especially for the power station boiler, industry boiler and coal plant waste water purifying and filtering engineering. After the new process depositing +micro-pored ceramic filtering treatment, the suspending materials removing ratio is up to 91-97%, outlet suspending materials is 10-15mg/L, COD removing ratio is more than 65%, the water quality is limpidness and transparence, is realized closed-circle using and zero outlet aim.

micro-pored ceramic main property index

item | index | item | index |

Volume weighkg/m3 | 1480 | Bend strengthMpa | 5.3 |

Pore diameterum | 10-500 | Anti-acid% | 98 |

Pore ratio% | 30-43 | Anti-alkali% | 74-82 |

Water penetrabilitykg/m2.h | 15000 | hardnessmohs | 7 |

Gas penetrabilitynm3/m2.h | 1.8-5.0 | Thermal stability | 200-19 |

Compression strengthMPa | 14 | Water absorption% | 23.3 |

micro-pored ceramic filtering tube specification

size | Out diameter mm | In diameter mm | Length mm | Connected head | width | Conhead width |

WCZ-50- | 50 | 30 | 500 | 66 | 15 | 8 |

WCZ-50- | 75 | 30 | 700 | 88 | 15 | 8 |

WCZ-100 | 100 | 60 | 700 | 120 | 20 | 10 |

WCZ-120 | 150 | 100 | 1000 | 180 | 25 | 15 |

WCZ-200 | 200 | 140 | 1000 | 230 | 30 | 15 |

微孔陶瓷过滤管

1、产品概述

微孔陶瓷是由骨料颗粒、分离剂、成孔剂和稀土抗蚀剂四部份组成。经过高温烧结使其外表和内部开成相互连通的桥拱状启齿气孔。当流体从这些气孔中经过时,原水或液体中的悬浮物质、胶体颗粒、大分子有机物被截留在过滤介质表面,流体经过微孔通道产生各种物理效应,达到机械筛滤、净化扩散、流态化等功效。

2、性能特性

微孔陶瓷产品除具有普通陶瓷产品性能外,还具有其共同的特性:

a)除氢氟酸外,对一切腐蚀液均有优秀的耐腐蚀性。

b)耐热性能好,不会产生热变形,在500℃时运用效果不变。

c)耐寒、耐冻性能优秀。

d)微孔散布平均,可按用户请求构成500μm以下各种孔径。

e)由于刚性大,因此在流体压力作用下不惹起外形变化和细孔变形,从而产品应用过程中易于清渣和再生。

f)在液体中无溶出物,因而液体不会遭到二次污染。

3、技术指标

项目 | 指标 | 项目 | 指标 | 项目 | 指标 |

密度(g/cm3) | 1.6-2.0 | 热稳定性(℃) | 350-20 一次不裂 | 透水率(t/m2h) | 10-2.5 |

吸水率(%) | 23.3 | 孔径(um) | 10-500 | 耐碱性(%) | 86 |

耐磨性(%) | 98 | 孔隙率(%) | 30-40 | 透气率(m3/m2h) | 1.8-5.0 |

坑折强度(Mpa) | ≧5.3 | 硬度(莫氏(MOhs’)) | 7 | 抗压强度(Mpa) | 12-16 |

4、主要型号规格 过滤陶瓷砖、板、管的型号规格

型号 | 微孔板 长X宽X高 | 型号 | 微孔砖 长X宽X高 | 型号 | 微孔管 长X宽X高 |

NCB-1 | 250X125X50 | NCZ-1 | 230X113X65 | NG-50 | 60X10X500 |

NCB-2 | 250X250X50 | NCZ-2 | 230X113X60 | NCZ-50 | 60X10X1000 |

NCB-3 | 300X300X60 | NCZ-3 | 230X113X55 | NCZ-80 | 100X20X500 |

NCB-4 | 330X330X60 | NCZ-4 | 230X113X50 | NCZ-80 | 100X20X1000 |

NCB-5 | 500X500X60 | NCZ-5 | 230X113X45 | NCZ-100 | 200X30X500 |

NCB-6 | 700X700X60 | NCZ-6 | 230X113X40 | NCZ-120 | 200X30X1000 |

注:规格尺寸还可依据用户请求作恰当调整。

5、应用范围

微孔陶瓷由于具有耐高温(寒)、耐化学腐蚀、强度高、气孔散布平均,运用寿命长且再生烦琐等优点,在许多行业都能够应用。其应用根本上可分两品种型,一是用于两种物相别离;二是把一种物相分散到另一种物相之中,也就是使两相分离,特别是用于液相过滤、气体过滤、流态化等方面。

在环保范畴内,废水化学混凝后污泥、絮凝体的过滤、脱水;离子交流法、电解法、活性炭吸附法处置废水的预处置;锅炉湿法除尘废水中悬浮物的过滤处置(可完成闭路循环);气浮法与蒸发浓缩的终端处置;含油废水的油水不别离处置;放射性废物燃(焚)烧排气过滤代集放射性物质;放射性废物库或渣滓填埋场做垫层,使之浸透废水经暗沟流入集水池中处置,可避免二次污染;用于烟气过滤,过滤含锌、锡、镍等电镀废水的过滤和电解槽母液的过滤处置,简化了流程,俭省了投资。

在工业范畴内,可用于四环素消费中的晶体过滤;化工双氧水消费中的水质过滤;感光胶片消费中的杂质过滤;立德粉消费中的硫化锌过滤;各种结晶物的过滤等。也可用于自然气过滤;紧缩空气过滤灰尘、水滴、油雾;二氧化碳气体滤除粉尘;过滤各种有机溶剂,脱炭、精制溶液石油开采炼制前除去原油中水份,油水别离等;油田回灌水杂质过滤,过滤蒸气、氯气、氧气、焦炉气、三氧化硫、五氧化二氮、二氧化碳、甲烷、氢气、乙炔、二氧化硫中的尘埃、杂质等;空气、蒸汽消毒过滤等,散气、布气充气,把气体分散到液体中,如有色金属浮选;各种自来水、工业用水、海水淡化、纯水、超纯水制备的过滤处置;各种酒、饮料、葡萄糖的盐水过滤;还可作为催化剂载体等。