Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

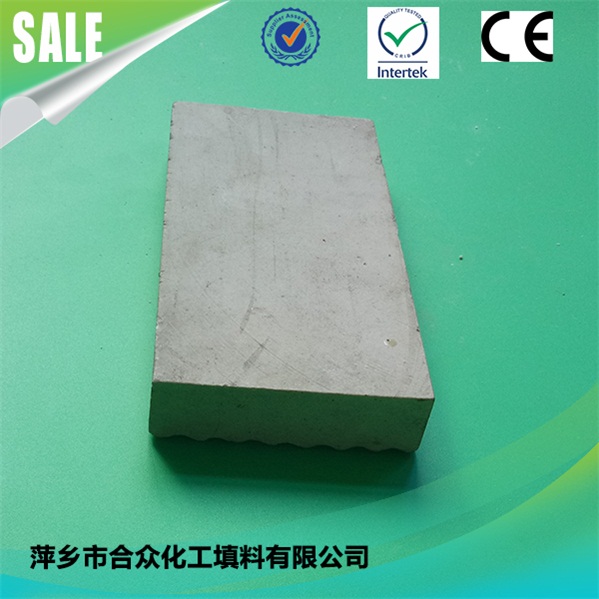

- Shape:

Brick

- Material:

Alumina Block

- SiO2 Content (%):

15%~40%

- Al2O3 Content (%):

40-77%

- MgO Content (%):

0.0

- CaO Content (%):

0.0

- Refractoriness (Degree):

Common (1580°< Refractoriness< 1770°)

- CrO Content (%):

trace

- SiC Content (%):

trace

- Model Number:

Al2O3 brick

- Brand Name:

HEZHONG

- standard size:

230x114x65

- Fe2O3:

Max 1%

- classification temperature(℃):

1300-1600

- permanent linear change:

0.6-1.01

- modulus of rupture (mpa):

1-3.2

- Cold crushing strength Mpa min:

1.2-3.5

- Bulk Density, g/cm3:

<1.1

- color:

white

- Certificate:

ISO9001

- Application:

Cracking furnace Conversion furnace Heating equipment and so on

| Product Name | Level 1 High Alumina Bricks | Level 2 High Alumina Bricks | Level 3 High Alumina Bricks | Special High Alumina Bricks |

| Model | LZ-75 | LZ-65 | LZ-55 | LZ-80 |

| Al2O3 %≥ | 75 | 65 | 55 | 82 |

| Fe2O3 %< | 2.5 | 2.5 | 2.6 | 2 |

Bulk Density (g/cm3) | 2.5 | 2.4 | 2.3 | 2.6 |

| Cold Crushing Strength Mpa> | 70 | 60 | 50 | 80 |

| Refractoriness Under Load ℃ | 1510 | 1460 | 1420 | 1550 |

| Refractoriness ℃> | 1790 | 1770 | 1770 | 1790 |

Apparent Porosity %< | 22 | 23 | 24 | 21 |

| PLC % | -0.3 | -0.4 | -0.4 | -0.2 |

1.Description

Our supply range of high alumina bricks are useful in the construction of steel refining furnaces, glass tanks, ceramic kilns, enamel kilns and rotary cement kilns. The high alumina bricks comprise of a blend of alumina and ferrous content and their apparent porosity is 15 to 23%. They have high refractoriness and can sustain themselves easily even in high temperature. This is the reason why they are used as high temperature equipments in various industries. These high alumina bricks are highly resistant to corrosion due to metal fluid and oxidation.

2.Feature

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

3.High alumina bricks Application:

High alumina brick is widely used for widely used in blast furnaces, hot bast stove,steel ladle lining, reheating furnace, cement kiln, tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , steel smelting furnace and various kiln lining and thermotechnical equipment, etc.

耐酸砖

产品概述

耐酸砖,是以石英、长石、粘土为主要原料,经高温氧化分解制成的耐腐蚀材料,具有耐酸碱度高,吸水率低,在常温下不易氧化,不易被介质污染等性能,除氢氟酸及热磷酸外,对温氯盐水、盐酸、硫酸、硝酸等酸类及在常温下的任何浓度的碱类,均有优良的抗腐作用。广泛应用于石油、化工、冶金、电力、化纤、造纸、制药、化肥、食品、乳业、果汁、电镀室以及塔、池、罐、槽等防腐工程,并在地下污水道和露天地面等工作地都可发挥其耐腐蚀力。

产品特点

(1)耐酸砖板具有耐酸度高、耐温耐酸效果好,吸水率低、在常温下不易氧化、不易被介质污染等性。

( 2)除氢氟酸以及热磷酸外,对湿氯、盐水、盐酸、硫酸、硝酸等酸类以及在常温下的任何浓度的碱类均有优良的抗腐蚀作用。

化学成分

成分 含量% 成分 含量%

siO2 60-70 MgO 0.1-0.8

al2O3 20-30 Na2O 0.5-3

FeO 0.5-3 K2O 1.5-2

CaO 0.3-1

物理性能

1类 2类 3类

吸水率% ≤0.5 ≤2.0 ≤4.0

抗弯强度/MPa ≥39.2 ≥29.4 ≥19.6

耐急冷急热℃ 100 130 150

试验一次后,试样不得有裂纹,剥落等破损现象

密度g/cm3 2.2-2.6

耐磨率g/cm2 ≤0.15

抗压强度MPa ≥100

导热系数W/(m2.k) 0.9-1.0

膨胀系数K-1 (5.3-6.4)×10-6

使用说明

1、一般环氧树脂,耐酸胶泥、耐酸水泥铺贴,铺贴时可根据上述生产厂家产品使用说明书进行施工;

2、用草酸清洗混凝土表面,达到酸碱中和;

3、工业瓷耐酸砖,间缝宽度约8--10mm,间缝深度与砖厚相平为宜,以防泄露;

4、铺贴完毕后应用草酸冲刷表面,以助于更加牢固。