Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

- Type:

Ceramic Parts

- Application:

Industrial Ceramic

- Material:

Alumina Ceramic

- Model Number:

ZT-heat exchanger ceramic honeycomb

- Brand Name:

HEZHONG

- Product name:

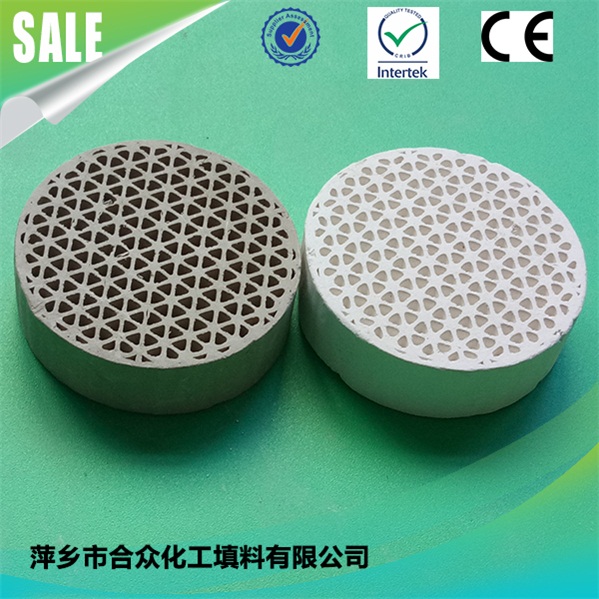

Ceramic honeycomb stone heat exchanger

- Color:

White/Black

- Size:

100*100*100/150*100*100/150*150*300

- Name:

heat exchanger ceramic honeycomb

- Density:

6.0g/cm3

- Highest Working Temperature::

800-1550℃

- Certificate:

ISO9001:2008

- Raw material:

Cordierite, mullite, alumina

Supply Ability

- Supply Ability:

- 500 Cubic Meter/Cubic Meters per Month Ceramic honeycomb stone heat exchanger & heat regenerator for RT

Packaging & Delivery

- Packaging Details

- Ceramic honeycomb stone heat exchanger & heat regenerator for RTO/RCO heat storage industry

1.In carton box then on pallet.

2.Inner Package:Carton

Outer Package:Wooden Case

- Port

- Shanghai or Shenzhen or Ningbo

- Lead Time :

- 15 days for 1/20fcl

Honeycomb ceramic for RTO RCO heat exchanger, regenerator, substrate, catalyst carrier 用于RTO - RCO换热器、回热器、基材、催化剂载体的蜂窝陶瓷

Specifications

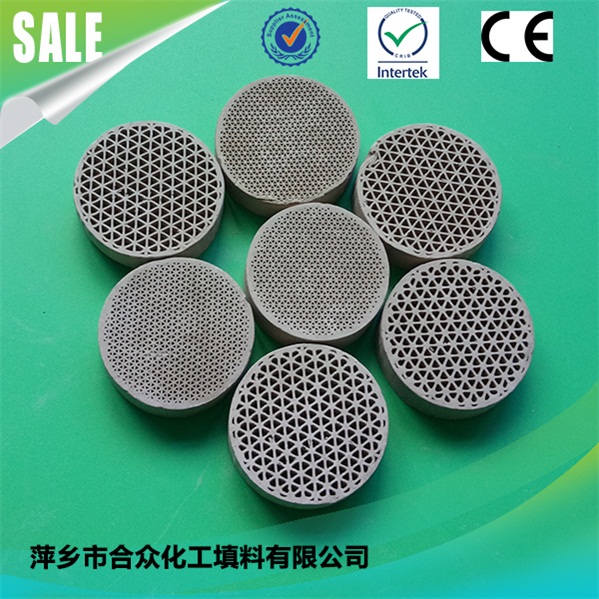

Honeycomb Ceramic For AUTO And Motor Catalyst Support

It make the gases more active and do oxide-reducing chemical reaction

Honeycomb ceramic:

1. High working temperature.

2. Large specifc surface area.

3.Good thermal conductivity.

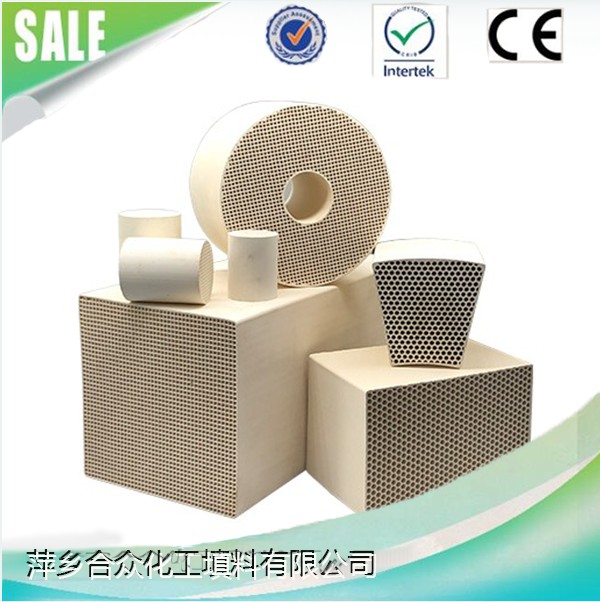

Honeycomb ceramic is a new developed porous industrial ceramic. As heat storage body, it has the properties of corrosion resistances, large specific surface area, small heat resistance, good thermal conductivity and excellant thermal-shock resistance performance, realize quickly exchanging heat and reducing energy, widely used in the industrial field. The honeycomb ceramic as the heat exchange media is the key part for heat storaging HTAC ( High Temperature Air Combustion) technology. It is the best choice for RTO, heat exchanger and other environmental protection and energy saving products.

Main Features of the honeycomb ceramic:

1. A new developed porous industrial ceramic.

2. Large specific surface area, corrosion resistance, small heat resistance, good thermal conductivity, excellant thermal-shock resistance.

3. Thermal energy storage.

4. We can produce the honeycomb ceramic series with different shapes and sizes according to customers’ requirements.

Application from the honeycomb ceramic: all kinds of pushing-steel heating furnace, RTO ( Regenerative Thermal Oxidation), stepping heating furnace, heat treatment furnace, forging furnace, dissolving furnace, steel wrapping/middle wrapping baking apparatus, soaking pit, radiation tap incendiary apparatus, covering furnace, high temperature hot-blast stove in metallurgical machine building, all kinds of ceramic cellar stove, glass cellar stove in building materials, all kinds of tap heating stove, splitting stove, other industrial stove cellar, etc.

?

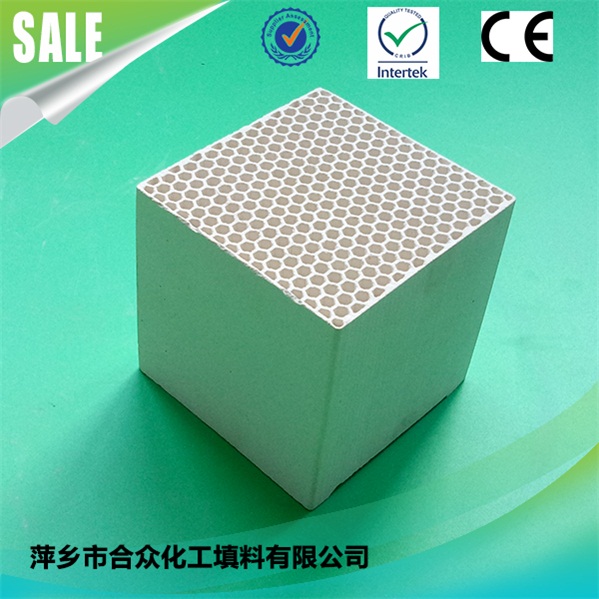

Specifications of the honeycomb ceramic:

Dimension (mm) | Hole Number (mm) | Wall Thickness (mm) | Specific Surface Area (m2/m3) |

150×150×300 | 25×25 | 1.0 | 573 |

150×150×300 | 32×32 | 0.9 | 785 |

150×150×300 | 40×40 | 0.7 | 883 |

150×150×300 | 43×43 | 0.65 | 1000 |

150×150×300 | 50×50 | 0.7 | 1050 |

150×150×300 | 60×46 | 0.5 | 1316 |

Technical Data of the honeycomb ceramic:

| Index | Metric Unit | Value |

Material Density | g/cm3 | 2.3-2.6 |

| Average Linear Expansion | 10-6/k-1 | <2.5 |

| Special Heat Capacity | KJ/Kg | 900-1200 |

| Heat Conductivity | W/MK | 1.8-3.0 |

| Max. Application Temp. | °C | 1350 |

| Acid resist strength wt.loss | % | <4 |

| Water Absorption | % | <5 |

Chemical Composition of the honeycomb ceramic:

Composition | Stoneware | Cordierite | Mullite Cordierite |

SiO2 | 41~45 | 53.55 | 29~30 |

Al2O3 | 34~37 | 39.65 | 68~69 |

MgO | 5.0~7.0 | 3.4 | -- |

Fe2O3 | 1.3~1.5 | 0.65 | 0.5~0.7 |

Na2O+K2O+CaO | 1.2~1.4 | <1 | 0.7~0.9 |

TiO2+BaO | 0.20~0.25 | 1.5 | -- |