Overview

Quick Details

- Place of Origin:

Jiangxi, China (Mainland)

- Brand Name:

HE ZHONG

- Model Number:

125X/Y 160X/Y 250X/Y 350X/Y 450X/Y 500X/Y 700X/Y

- Application:

Heat Exchanger, Distillation Tower, Adsorption tower

- Shape:

Customize

- Material:

Ceramic, Metal, Plastic, Ceramics

- Dimensions:

Customize dimension

- Chemical Composition:

99.95%Min

- Product name:

Ceramic Corrugated Structured Packing as Heat Exchanger

- Keywords:

Ceramic Corrugated Structured Packing

- Merits:

Low pressure drop, high capacity

- Size:

150mm height with customize dimension

- Type:

125X/Y 160X/Y 250X/Y 350X/Y 450X/Y 500X/Y 700X/Y

- Usage:

Thermal & Heat transfer media

- Crush strength:

≥130 MPa

- Water absorption:

≤0.5 Wt%

- Moh's Hardness:

≥7 Scale

Supply Ability

- Supply Ability:

- 6000 Cubic Meter/Cubic Meters per Year Ceramic Corrugated Structured Packing as Heat Exchanger

Packaging & Delivery

- Packaging Details

- Carton box, plastic bag with pallet, wooden case or as per customer's request.

- Port

- Qingdao, Shanghai

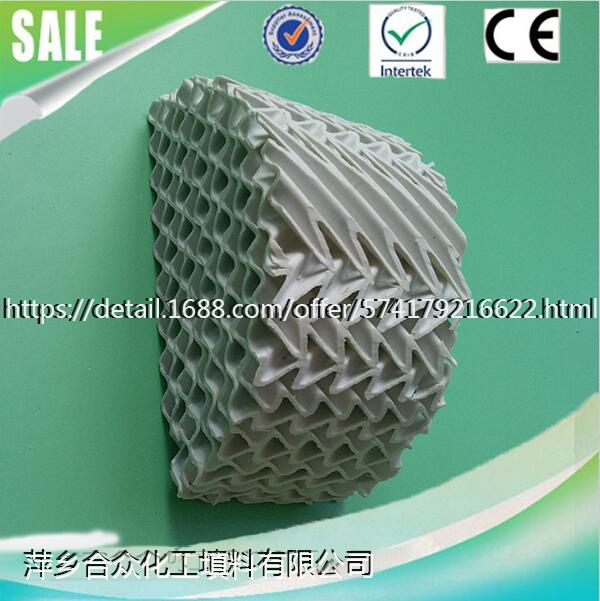

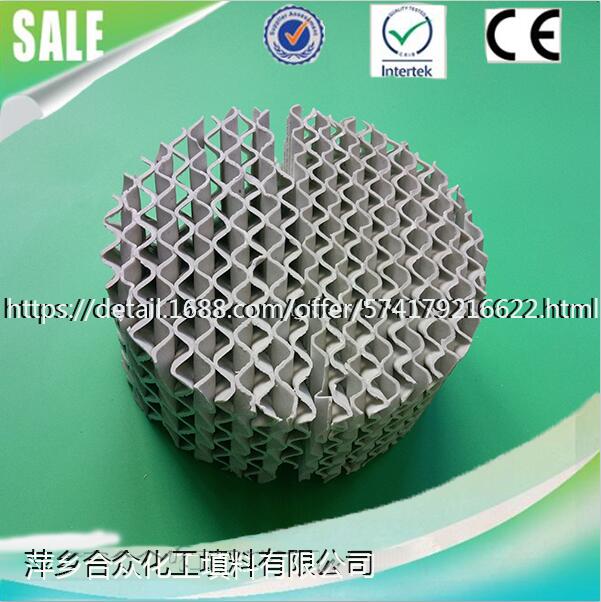

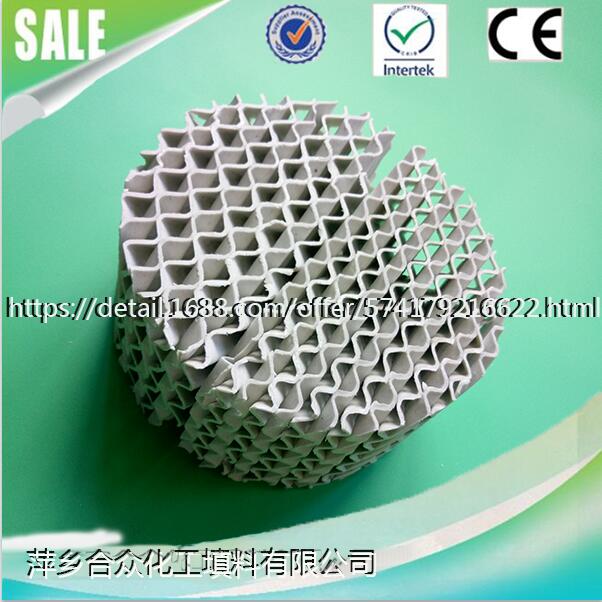

Ceramic Corrugated Structured Packings for Separation of Distillation and Absorption 陶瓷波纹规整填料用于分离蒸馏和吸收

Ceramic structured packing is a kind of column shape and single layer corrugated packing,consisting of many moire pieces with the same geometric shape and parallel to each other. According to the different obliquity of corrugated sheet,this product is divided into X-style and Y-style,and X and Y correspond to the 30 °c and 45°c respectively. Ceramic structured packing has a series of advantages,such as high efficiency,low pressure drop, great treatment, little liquid content, unremarkable amplifying effect and high elasticity in operation. With a unique structure,and excellent hydrophilic performance, the very thin liquid film can be formed in the surface of ceramic,and the flow of liquid film as well as oblique and flexural channel ensure the smooth airflow , and don't impede it,making the efficiency of this product comparable with metallic corrugated packing. Dohntec makes the production of different specific surface area and flexible standard structured packing in terms of customer's demands.

Ceramic structured packing is not only widely used in coal gas washing tower, fertilizer heat gas saturation tower, naphthalene washing tower, ammonia washing tower, but also as the support for heat exchange machine , catalyst, and suit for a big tower rebuilding/revamp.

Advantage:

The most economical range is F-factor 1.5-2.0

Pressure drop of each theoretical sheet is 0.3-1 mbar

Minimum liquid load is 2001/m2h

A distributor should be installed for every 3-4 meters inside packing towers with diameters of more than 300 mm

Features:

High liquid & vapor loading, Column diameter could be designed smaller for new equipment and capacity could beincreased dramatically for existing column revamp.

High resistance to nearly all mineral and organic acids and derivatives, partly resistant to alkalis

High mass-transfer efficiency. Much higher specific surface area than random packing

Low pressure drop, considerable energy savings

Wide turndown ratio. Easy to scale up

Suitable for all sizes of column

Application:

Ceramic structured packing was not only widely used in coal gas washing tower, fertilizer heat gas saturation tower, naphthalene washing tower, ammonia washing tower, but also as the support for heat exchange machine , catalyst, and suit for a big tower rebuilding/revamp..

Fining process of corrosive mixtures, which have strict requirements for pressure drop and number of theoretical sheets.

Vacuum treatment under absolute pressure higher than 1 mbar.

Fining and distillation of halogen organic compounds.